Plan Review Guide

Table of Contents

Introduction

This page lists basic instructions for completing the different components of the plan review application.

Facility Plans

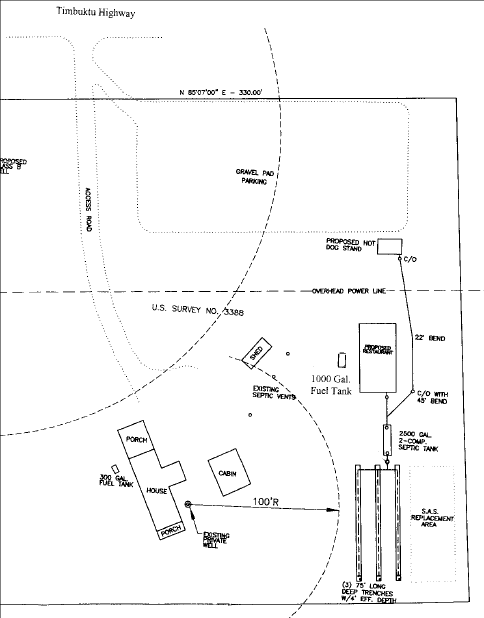

Plot Plan

A facility plot plan is a miniature representation of the outside of your facility as seen from an aerial view. These plans can be drawn by either the owner/operator or a professional. However, the plans must be legible and to scale, which means that everything must be in the correct proportions.

What to include:

- All buildings (including sheds, storage warehouses, employee housing, etc.)

- Outside walk-in cooler(s)/freezer(s)

- Refuse storage site

- Identify nearby roads, streets, other landmarks, and/or give GPS coordinates

- Outside storage areas

- Potable water supply

- Oil/fuel tanks

- Access for deliveries

- Sewage disposal system

Example facility plot plan

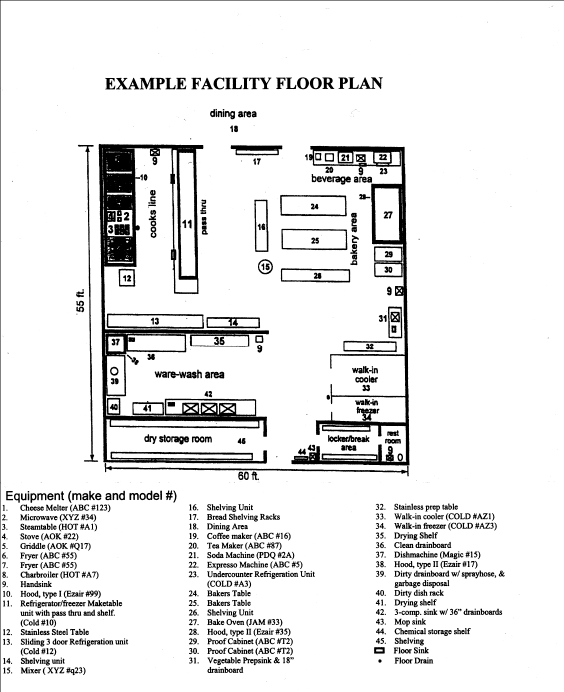

Floor Plans

A floor plan is a measured drawing that is an exact miniature representation of your establishment as seen from an overhead view. These plans can be drawn by either the owner/operator or a professional. However, the plans must be legible and to scale, which means that everything must be in the correct proportions. If your establishment does not yet exist or if you have not decided upon the exact equipment, your measurements will be estimates.

What to include:

- Layout and purpose of each room

- Location of fixed equipment and plumbing features

- Location of restrooms, including the number of toilets and handwash sinks

- Type and location of lighting

- Type and location of ventilation, both building and local systems

- Size, construction, and design of fixed equipment

How to draw a floor plan:

- For facility in an existing building, begin by measuring, with a tape measure, the length and width of your establishment as well as the lengths and widths of all interior rooms including kitchens, dining rooms, bars, store rooms, walk-in coolers, etc.

- Next, measure the length and width of all sinks, tables, worktables, counter tops, and other equipment throughout the establishment.

- Write down all your measurements for future reference.

- Draw the plan on graph or quad paper that is at least 8.5" x 11" with a minimum scale of 1/4" = 1'. Draw all interior rooms, walls, hallways, and doorways according to your measurements.

- Include all the equipment, sinks, and tables, etc., positioned accurately on the plan. Identify each piece of equipment with a number. (this includes all sinks.)

- Create a list identifying each number to the item depicted.

Example facility floor plan

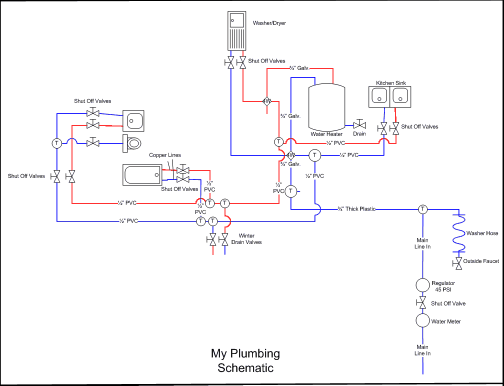

Plumbing Schematic

A plumbing schematic is a basic drawing that illustrates where your hot and cold water lines and wastewater lines would go. Be sure to include if a drain line is directly or indirectly connected.

What to include:

- Plumbing schematic showing each hot, cold, and wastewater line.

- The hot water capacity.

- If the connections to the sewer are direct or indirect connections.

Example Plumbing Schematic

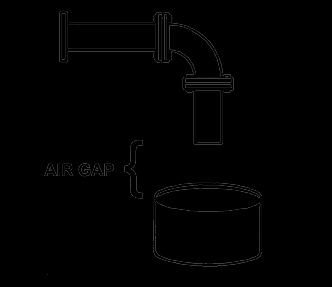

Indirect Connections

A direct connection may not exist between the sewage system and any drains originating from equipment in which food or drink is stored, prepared, or served. This includes refrigerators, steam kettles, ice storage bins, and food preparation sinks.

Example indirect connection to the wastewater lines

Determining Hot Water Demand

An adequate supply of hot water for washing hands, utensils, equipment, and for cleaning the facility is required. A properly sized water heater will ensure that a sufficient amount of hot water is available at all times.

The hourly hot water demand in Gallons Per Hour (GPH) for a food establishment is calculated by adding together the estimated hot water demands for all sinks and other equipment that use hot water. Please use the Hot Water Heater Calculation Worksheet to help determine what size hot water heater you will need. Items noted in bold below are required equipment. All others are optional. However, you must list out all sinks and equipment in your facility to calculate the proper hot water demand.

| Equipment | Quantity | GPHMulti-use utensilsSingle service utensils | GPH Subtotal |

|---|---|---|---|

| Food Prep Sink | 15 | ||

| Three Compartment Sink | 60 | ||

| Pre-Rinse Spray Hose Sink | 45 | ||

| Commercial Dishwashing Machine | |||

| Bar Three Compartment Sink | 20 | ||

| Chemical Sanitizing Glass Washer | 60 | ||

| Handwash Sink - Kitchen & Restroom | 5 | ||

| Bain Marie | 10 | ||

| Utility Sink | 10 | ||

| Garbage Can Wash Station | 30 | ||

| Clothes Washer | 45 | ||

| Employee Shower | 20 | ||

| Total | |||

| *Refer to manufacturer's specifications for gallons per cycle. Multiply by cycles per hour to yield GPH | |||

The average temperature of tap water varies throughout the state depending upon the location, elevation, and time of year. Temperature Rise is defined as the temperature needed to raise tap water to reach a temperature of 110°F. For example, if your tap water was at 35°F, the temperature rise for your system would be 75°F. A note about different types of hot water heaters:

- Instantaneous water heaters must be sized to provide hot water of at least 110°F at a rate of at least 2 Gallons Per Minute (GPM) to each non-hand wash sink and fixture that uses hot water. Hand wash sinks need at least ½ GPM each. (Note: Most instantaneous hot water heaters only provide 2-3 GPM).

- Gas water heaters will be assumed to have a Thermal Efficiency of 75% (0.75) unless otherwise listed by NSF International or other nationally recognized testing laboratories.

- Electric water heaters will be assumed to have a Thermal Efficiency of 98% (0.98) unless otherwise listed by NSF International or other nationally recognized testing laboratories.

Power Input = GPH * Temperature Rise * 8.33 lb./gallon of water / Thermal Efficiency

Sample Problem For Sizing Water Heaters

An operator proposes to open a new foodservice establishment with a full service menu using multi-service utensils. There will be a three-compartment sink, 3 hand wash sinks (2 in restrooms and 1 in preparation area), and a utility sink.

Using the Hot Water Heater Calculation Worksheet, the total gallon per hour (GPH) comes to 85. (60 for one three compartment sink, 5 x 3 = 15 for the hand wash sink, and 10 for one utility sink).

x /0.75

Calculating Storage Capacity

Two types of storage are found in food establishments: refrigerated storage and dry storage. Adequate storage space is dependent on the frequency of deliveries, the volume of business, and the menu type. Below are some examples of how to calculate the amount of refrigerated storage and dry storage you food establishment will need.

You will note the amount of storage space in Section C of the Plan Review Supplement Application.

Calculating Refrigerated Storage

At a minimum a food service should consider having enough space to handle the supplies needed over a weekend (i.e., three days). Also take into consideration how many and what items a typical meal on the menu takes. A meal of a soup and sandwich would be less than a meal that consists of appetizers, salad, soup, main course with vegetable and potato, and dessert.

To first plan refrigeration storage these items need to be taken into consideration:

- Days between deliveries

- Meals per day

- Typical volume per meal - 0.037 to 0.085 cubic feet on average depending on composition:

- Meat, Poultry, & Seafood = 0.010-0.030 cubic feet per meal

- Dairy = 0.007-0.015 cubic feet per meal

- Vegetables & Fruits = 0.020-0.040 cubic feet per meal

- Useable space in refrigeration unit - Only 40% of the refrigeration space such as in a walk-in provides useable space.

The following is a suggested formula to establish required reserve refrigeration storage:

Days between deliveries x Meals per day x Volume per meal / Useable space = Reserve refrigeration storage

x x x 0.40 = X Cubic Feet

To calculate the interior space (in square feet) required, divide the volume by the height of the unit.

X Cubic Feet / = X Square Feet

To get an estimate of the total exterior floor area required, multiply this number by 1.25.

X Square Feet x 1.25 = X Square Feet

Calculating Dry Storage

There are two suggested formulas shown below. Volume per meal is estimated at 0.025 to 0.050 cubic feet per meal. Consideration in determining which value to use would depend on whether single service utensils (i.e. paper plates, cups, and tableware) are used. Also to take into consideration for caterers is storage area for the portable catering equipment used.

Days between deliveries x Meals per day x Volume per meal / Depth of shelves x Height between shelves x 0.80 effective capacity of shelf height

days x meals/day x ft^3/meal / ft x ft x 0.80 = X Linear Feet

Days between deliveries x Meals per day x Volume per meal / Average height of storeroom x Fraction of useable storeroom area (0.3-0.6, typically)

days x meals/day x ft^3/meal / ft x = X Linear Feet

Equipment

A list of equipment must be included with the plan review packet. This will help to determine that the equipment complies with menu needs and capacity. List on a separate sheet of paper all of the equipment in your kitchen.

What to include:

- Refrigeration equipment

- Hot holding units

- Freezers

- Hood systems

- Steam tables

- Any equipment that may be found in the equipment

An example of an equipment list:

Equipment List

- Walk-in Freezer

- Walk-in Refrigerator

- 4 Tier Stainless Steel Shelving

- Entry Door

- Hand Sink

- 3 Compartment Pot Sink

- Stainless Steel Overshelf

- Ansul Fire System

- Full Size Floor Model Deep Fryer

- Flat Top 36" Griddle

- 6 Burner Range with Oven Below

- 200 Amp, 1 Phase Panel

- Utility Room Exhaust Fan

- Stainless Steel Exhaust Hood

- 40 Gallon Tilting Skillet

- Dual Stack Convection Oven

- 36" Charbroiler

- 60"x24" Stainless Steel Counter with Undershelf

- 48"x24" Stainless Steel Clean Dish Table

- Dry Storage Area

- Utility/Mop Sink

- Freezer Compressor

- Refrigerator Compressor

Plan Review Checklist

Below is a checklist to assist you with building your facility. Please refer to the Alaska Food Code (18 AAC 31) for further details.

Equipment Specifications

| All sinks are self-draining. (Sink compartments drain completely with no pooling water.) |

| Dishwashing |

|---|

| Sink compartments are adequate for the complete immersion of most equipment and utensils. |

Dishwashing machine (if provided)

|

| The operator of a bar or tavern shall ensure that a 4th sink compartment, or separate handwash sink, is installed for dumping drinks and handwashing. |

Indicates an external site.

Indicates an external site.