Soil Treatment by Thermal Desorption

Table of Contents

- What is Thermal Desorption

- How do Thermal Desorption Facilities Operate?

- How are Thermal Desorption Facilities Regulated in Alaska

- How will DEC ensure the facilities are operating in accordance with their Operations Plan?

- How Will DEC Ensure the Property is Not Contaminated When a Facility closes?

What is Thermal Desorption?

Thermal desorption is a method used to treat contaminated soil. The following information comes from the Environmental Protection Agency’s (EPA) A Citizen’s Guide to Thermal Desorption:

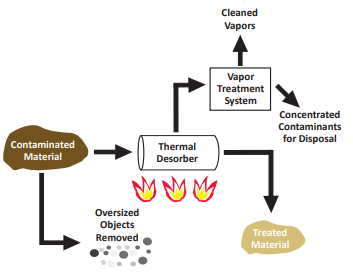

Thermal desorption removes organic contaminants from soil by heating them in a machine called a "thermal desorber." This evaporates the contaminants. Evaporation changes the contaminants into gases and separates them from the solid material.

Thermal desorber heats contaminated material to evaporate contaminants. Courtesy: EPA A Citizen's Guide to thermal Desorption

The desorber can be used onsite or offsite. Soil may be prepared for treatment by screening out debris and oversized material. The prepared soil is placed in the thermal desorber to be heated.

Gas collection equipment captures the contaminated vapors. Vapors are destroyed in the thermal oxidizer, which heats the vapors to temperatures high enough to convert them to carbon dioxide and water vapor.

It is important to note that thermal desorption is not the same as an incinerator which heats contaminated materials to temperatures high enough to destroy the contaminants.

For more details on thermal desorption, please see EPA’s A Citizen’s Guide to Thermal Desorption.

How do thermal desorption facilities operate?

Petroleum-contaminated soil is delivered and placed into a staging area with a bermed petroleum-resistant surface with a retractable cover.

Soil is screened to remove all rocks and material over 2-inches in diameter. Any oversized rocks and material are pressure-washed in containment to remove any residual soil which will be added back into the screened soil. The screened soil is stockpiled on a petroleum-resistant, sealed, asphalt pad in a covered containment area while awaiting treatment. The soil is then transferred onto a conveyor belt leading to a dryer drum.

The soil is heated in the dryer drum to 700° Fahrenheit to remove the contaminants, which are discharged to the baghouse as vapors and fine particulate. A baghouse uses filter bags to filter gases and fine particulate. Filtered gases are pulled out of the baghouse by a fan into the secondary treatment unit (thermal oxidizer). The thermal oxidizer heats up to 1,400°-1,600° destroying organic vapors. Gases that are emitted are monitored in accordance with the permit issued by DEC’s Division of Air Quality.

Fine material from the baghouse filters is mixed back with the soil and both go to a conditioner that cools and rehydrates the treated soil. The soil then moves onto a radial stacker which creates a stockpile on a steel plate pad. The post-treated soil storage cells are covered with polyethylene liners when treated soil is not being actively stacked.

The soil remains on the pad until post-treatment sample results demonstrate that the soil meets the most stringent cleanup levels for the contaminants of concern. Once the soil analytical test results show that the soil has been successfully remediated, it can be returned to the original contaminated site or stockpiled at the facility for use by other contractors for projects.

Waste water generated during soil washing and stormwater is collected in a sump and treated using granular activated carbon before surface discharge. Water samples are collected periodically to ensure the treatment system is working efficiently.

How are thermal desorption facilities regulated in Alaska?

The DEC Contaminated Sites Program’s regulatory authority to review and approve of offsite and portable treatment facilities is 18 AAC 75.365 and 18 AAC 78.273. Operations plans are reviewed according to these regulations and the Operation Requirements for Soil Treatment Facilities (DEC 2013) guidance adopted by regulation.

How will DEC ensure the facilities are operating in accordance with their Operations Plan?

The DEC Contaminated Sites Program has multiple systems in place to ensure a facility is operating according to regulation and their operations plan. First, according to the Alaska regulations, soil cannot be accepted by a facility without written approval from a DEC Contaminated Sites or Prevention, Preparedness, and Response project manager. When petroleum-contaminated soil is identified, the Responsible Party (contaminated soil waste generator) or their consultant will contact a facility to see if they can bring the contaminated soil to the facility and will complete a Contaminated Media Transport and Treatment or Disposal Approval Form. The form will be sent for review to DEC staff already working with the Responsible Party. The DEC staff will review the information about the contaminated site or spill to ensure the contaminants present in the soil are limited to petroleum or petroleum constituents before approving the transport of contaminated soil to the facility.

Secondly, following the treatment of each batch of soil, the facility will submit analytical results of post-treatment samples to DEC for review and comparison with the most stringent cleanup levels before the soil can be released. These samples must be collected by an impartial third-party who meets the DEC regulatory requirements of a Qualified Environmental Professional or Qualified Sampler.

Finally, thermal desorption facilities submit an annual report to the DEC Contaminated Sites Program which documents inspections and maintenance of the pad, water treatment discharge results, and annual groundwater well sample results. The DEC Contaminated Sites Program staff will conduct facility inspections as well.

How Will DEC Ensure the Property is Not Contaminated When a Facility closes?

Facility closure requirements are described in regulation and outlined in Section 7 of the Operations Plan. ???STT has conducted a baseline assessment of the property to determine the conditions of the soil and groundwater prior to facility operations???. At the time of closure, a closure assessment will be conducted within 90 days of the end of the operations. The facility will provide a work plan for DEC for approval to ensure the assessment meets DEC’s requirements at the time of closure. The contaminated soil containment cell and post-treatment soil containment will be removed and the underlying soil will be sampled to make sure that it isn’t contaminated. An impartial third-party Qualified Environmental Professional will prepare a report for review and approval by the DEC Contaminated Sites Program. Any cleanup needed following the closure assessment is required to be completed within two years.

Indicates an external site.

Indicates an external site.