New Applicants and Owners

If you are a new operation or a new owner to an existing operation, you're in the right place!

If you are an existing permit holder and wish to renew, please email seafoodprocessing@alaska.gov or call 907-269-4552 for your pre-filled renewal application.

Please be aware of the following before applying!

- It may take up to 30-60 days for applications to be reviewed.

- Application review will not start until a completed application is received and the fee is paid.

- All applicants are required to complete all portions of the application with accurate and correct information.

- Approved permits be sent to the business email address provided on the application or you may contact us for a paper copy.

- A processing charge of $71.00/hour for time spent on application processing/review will be deducted from the permit fee paid for withdrawn and denied applications.

As you fill out the online application, you will need the following resources. It is recommended that you bookmark these links for future reference:

- 18 AAC 34 Seafood Processing and Inspection

- 21 CFR Part 123 Fish and Fishery Products

- 21 CFR Part 101 Food Labeling

- 21 CFR Part 102 Common or Usual Name for Nonstandardized Foods

- 21 CFR Part 161 Fish and Shellfish

- 4thEdition Fish and Fishery Products Hazards and Controls Guidance

Online application for Seafood Processors and Ice Manufacturers:

Application Instructions for Seafood Processors and Ice Manufacturers

Application Requirements

All Applicants: All applicants must complete the online seafood application and attach all the following documents when prompted to do so by the application form

- Site Plan

- Floor Plan with List of Fixed Equipment

- Plumbing Schematic

- Product Label

- Sanitation Plan (SSOP) (18 AAC 34.050)

- HACCP Plan

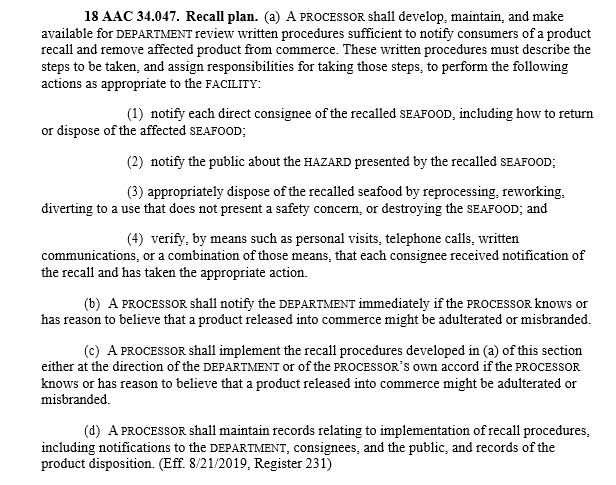

- Recall Plan (18 AAC 34.047)

Additional Documents: Some applicants may also be required to attach the following

- For Smoker Operations - Heat distribution study for smoker(s)

- For Cooking Operations - Cook Study

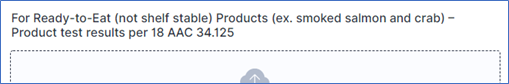

- For Ready-to-Eat (not shelf stable) Products (ex. smoked salmon and crab) - Product tests results as per 18 AAC 34.12

- For Operators Sharing a Facility Location - Lease letter agreement with the primary owner of the facility

- For Thermal Retort, Canning, or Freeze Drying Operations:

- FDA Forms 2541 and 2541(d)

- Process authority letters or schedule for all retort or canning processes

Using the Online Seafood Application

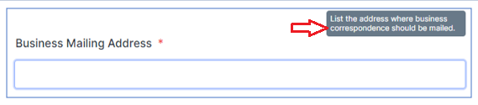

Hover Text: Most sections have quick instructions that appear when you hover over a section.

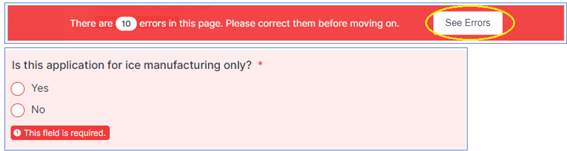

Required Fields: An error will appear if a required field was left blank. If this message appears at the top of the page, click See Errors and the form will bring you to each field that needs a response.

Once all errors are fixed, you will get a fixed message. Click Done to continue filling out the form.

![]()

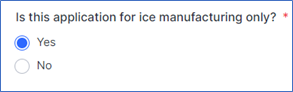

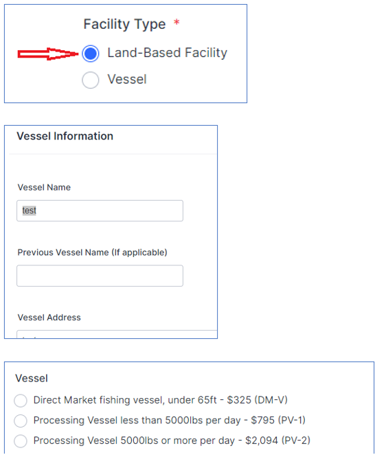

Smart Form: Some responses will affect what is displayed in other sections. If you find you are missing sections, you may have provided an incorrect response. Here are some quick troubleshooting tips to assist you:

Fish Resources, Process, Packaging are missing but I process seafood in addition to manufacturing ice: Most likely you have checked Yes for the ice manufacturing only question. You will need to go back and check No to get the processing portions of the application to show up.

My Facility is Land-Based but I’m only seeing Vessel Information and Permit Types: You may have checked Vessel under Facility Type at the beginning of the application. You will need to go back and check Land-Based Facility.

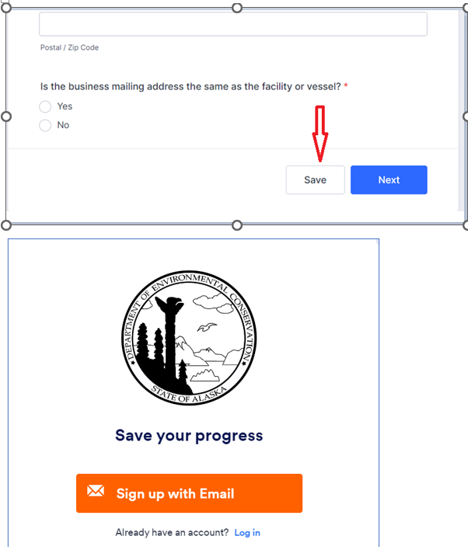

Saving Progress: If you would like to save your progress for later retrieval, click save at the bottom of the page and follow the pop-up prompts. You must create an account in order to access your application. If you closed out of these screens and do not have an email link, you will need to start the application over.

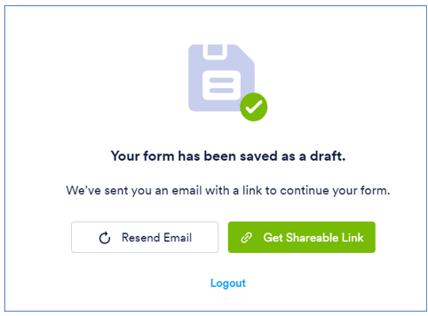

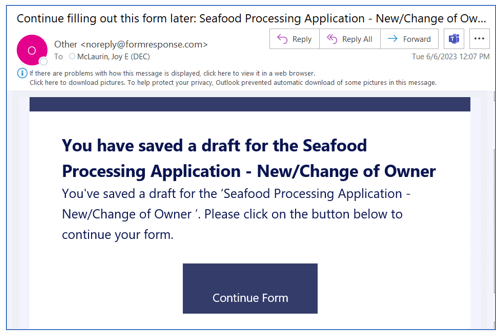

Once you are logged in, you will receive this message each time you save.

Before closing out of the application, make sure you have an email that looks like this with the link to your saved application.

Filling Out the Form

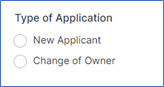

Type of Application

Select the application type that best matches why you are applying for a seafood processors permit, using the descriptions below as a guide.

New Applicant:

- New construction

- Leasing a new or existing facility

- Extensive changes to a facility or vessel, products, or process flow

Change of Owner/Operator:

- Business information changes

- Partial sale (some of the existing owners will continue to be owners after the sale)

- 100% change of owner/operator (DEC permits and files are not transferable. If there has been a 100% change of ownership, the new owner is required to submit a new permit application)

Type of Entity

Select the type listed on your Alaska Business License from the Department of Commerce.

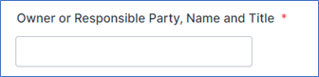

Owner or Responsible Party

List the individual that is legally responsible for the vessel or land-based facility.

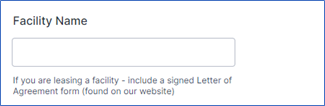

Facility Name and Leases

Facility Name: Type the name of the facility you will be processing out of.

Leases: If you are leasing space and/or equipment at an existing seafood processing, food manufacturing facility, or commercial kitchen:

- In the Facility Name, list the processors name and ‘at’ the name of the facility you are leasing from (for example: Joe Smith @ Petersburg Community Cold Storage or Joe’s Fish Processing @ Petersburg Community Cold Storage).

- Fill out, sign, and attach a Seafood Processing Facility Agreement form. If other operations will use this facility, you must include a description of how you will separate your processing activities from the other operations. If a dedicated space is not possible, you must include a time schedule that shows when you will be using the space. The schedule cannot overlap with processing times for other operations sharing the same space.

Note: This form is not the same as the tenant or rental agreement.

Facility Physical Address: This is the physical location or street address of the facility. Do not list PO Box numbers in this field. Include the city and zip if different from the mailing address. If there is not a street address for the physical location, fill out the Location Description section below.

Location Description: This is for physical locations that do not have a street address. Fill out the physical location of the facility (such as, Mile 1 Naknek Road). If the facility is not located on a road system, describe how you would get to the facility.

Vessel Name and Leases

Vessel Name: Indicate the registered name of the vessel where processing activities will take place.

Vessel Leases: If you are leasing the vessel, include a signed Seafood Processing Facility Agreement form.

- Do not use the vessel owner’s business information in the Owner/Business Information section. You need to list your own business information in this section.

Vessel Mailing Address: List the mailing address where the vessel manager receives mail during the harvest season.

ALASKA Port(s)/Mooring Locations: Provide the closest dock address or physical location where the vessel will be moored while in Alaska (ex. For offloads, resupply, crew change). If there is no street address, provide a location description such as, “Ketchikan Boat Harbor.” Include the city and zip code for this location.

This is also the location where the vessel will be available for inspection. If you do not plan on docking anywhere in Alaska, you must list one of the designated locations listed in 18 AAC 34.930 (i), as follows: Anchorage, Dutch Harbor, Juneau, Kenai, Ketchikan, Kodiak, Sitka, and Valdez, and coordinate the annual inspection with the area Environmental Health Officer. A list of DEC FSS offices can be found here:http://dec.alaska.gov/eh/fss/staff/.

Note: Department approval will be required for locations that are not listed, and may result in additional fees for inspection.

Product and Packaging Details

Everything checked in this section must be reflected on the label and HACCP documents.

If you are a new applicant or have made changes to: Fishery Resources, Processes, or Packaging Material, you must perform a Hazard Analysis, and if new hazards are identified, submit a new or updated HACCP Plan.

Check all that apply to your current operations. For future updates or changes within the permit year, send an email indicating the changes and include any updated documentation to: seafoodprocessing@alaska.gov.

Process Definitions

Roe: If you checked any of the roe processes, be sure to check Roe under A. Fishery Resource Utilized.

- Roe, Green (Unprocessed) - The process of compiling roe into blocks and freezing before going to secondary processor. This is typically done by larger processors.

- Roe - Recovery - Roe is collected in a bucket and offloaded to a processor. Typically done by smaller processing operations or direct marketers.

Ready-to-Eat (RTE): Ready-to-eat products are those that do not need to be cooked by the end consumer but are not shelf-stable or processed according to a schedule approved by a Process Authority.

Processes that produce RTE products are as follows:

- Cooking in Water

- Cooking in Steam

- Mixing or Formulating

- Acidifying

- Pickling

- Roe, Salted

- Salting or Brining

- Hot Smoking

- Cold Smoking

Process approval for RTE products requires testing on 12 randomly selected samples from the first lot produced, as per 18 AAC 34.125(a)(d)(1) and (2). You must submit these test results with your application documents.

Examples of RTE products (this is not a complete list):

- Hot or Cold Smoked Fish

- Pickled Fish

- Salted Roe (Ikura, Sujiko)

- Cooked Crab

- Boiled Sea Cucumbers

- Seafood Salads, Dips, or Spread

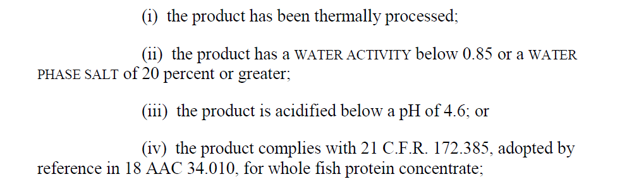

Shelf Stable: Products that meet the standards of 18 AAC 34.122(a)(6)(A), are capable of being stored at room temperature for extended periods without production of pathogenic or toxigenic microorganisms or product deterioration and (B) meets one of the following four standards:

Processes that produce Shelf Stable products are as follows:

- Drying*

- Dehydrating*

- Freeze Drying

- Canning or Retort (Thermal Processing)

*If you are producing a shelf stable product that is not processed according to a schedule that has been approved by a Process Authority, you must submit test results on one sample from the first lot produced for water activity.

Thermal Processing: Canned or retorted products that have been cooked according to a process schedule that has been approved by a Process Authority (Process Authority Letter) and registered with the FDA.

If you checked thermal, you must submit the following with your application:

- FDA forms 2541 and 2541 (d)

- Process authority letters or schedule for all retort or canning processes

Processes included under Thermal Processing are:

- Cooking with Steam

- Thermal

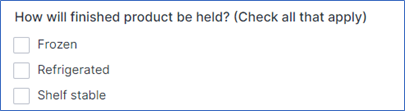

Finished Product Holding: How will your products be held during storage and/or transit?

Product Hold Definitions (18 AAC 34.990)

- Freezing (or Frozen) – to congeal or solidify the flesh of a seafood product by the removal of heat to an internal temperature of 5 degrees Fahrenheit or below in a room, plate freezer, blast freezer, or individual freezer, or to an internal temperature of 15 degrees Fahrenheit or below in a brine freezer.

- Refrigerate (or Refrigeration) – to maintain seafood products or an enclosed area at a temperature that is above freezing and at or below 45 degrees Fahrenheit.

- Note: Refrigerated also includes fresh products that are shipped on ice or with gel ice packs.

- Shelf-Stable – a seafood product that meets the standards of 18 AAC 34.122(a)(6)(A) and (B) is capable of being stored at room temperature for extended periods without production of pathogenic or toxigenic microorganisms or product deterioration.

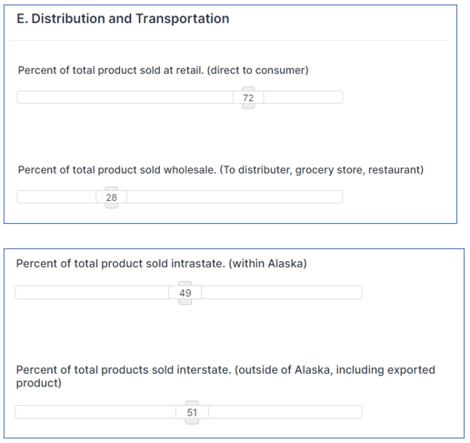

Distribution and Transportation: Using the slider bar, click on the ![]() and move it right or left until the number that displays reflects the percent for your operation. If this is a new operation, anticipated these percentages. They can be updated at the annual renewal.

and move it right or left until the number that displays reflects the percent for your operation. If this is a new operation, anticipated these percentages. They can be updated at the annual renewal.

The percentages must add to 100% for the following:

- Retail and Wholesale

- Intrastate and Interstate

Note: the Interstate percentage should include the Export percentage

Transportation:Describe how your product will be transported from your facility or vessel to the intended market (for example: loaded into a freezer van then flown on an airplane)

Seafood Processors Business Form A

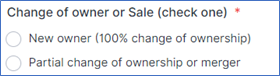

Change of Owner or Sale

New Owner (100% change of ownership): This option is for ownership changes where none of the former owners have any percentage ownership in the company after the sale is finalized.

Partial change of ownership or merger: This option is for partial changes or mergers where some of the former owners still have a percentage ownership in the company after the sale is finalized.

Note: A new permit number will be assigned for 100% change of ownership and in partial ownership changes where the direct relationship between the facility or vessel and the owner is broken.

If you are unsure which option best fits your situation, email us at seafoodprocessing@alaska.gov.

Seafood Plan Review Checklist

In this section, you will be asked to submit the following documents for the highest risk product produced:

- Product flow or narrative that describes all processing steps and includes any verification checks

- Sample product label

- HACCP Plan

Determining the highest risk product

Some factors to consider when determining if your product is considered high risk are as follows:

- The product has a high potential risk for microbiological or chemical contamination or has historically been associated with foodborne illness

- The product supports the growth of pathogenic microorganisms

- Post processing steps could potentially re-contaminate the product with bacteria

Ready-to-eat and shelf stable products pose the highest risk, as they are typically not cooked before consumption. Please see the Process Definition section above for a list of processes that produce high risk products.

Product Labels

Submit one master container (or case) label and one retail package label for each product you will be producing, that meets the requirements in 18 AAC 34.110. This can be hand drawn.

Each master container or case label must include the following:

- Placeholder for DEC permit or AK number

- Firm name and contact information (phone number, email, or mailing address).

- Note: websites are acceptable, however, they must be working at the time of application and include how to contact the firm. If we are not able to verify contact information from the website listed on the label, you will be asked to provide an updated label that includes working contact information.

- Net weight

- Date of pack

- Market or common name as specified in the FDA seafood list

- Common or usual name of each food ingredient, additive, or preservative

- Holding statement

- If the product is custom processed, a qualifying statement, such as, “packaged by” or “processed for”

Each retail package must include the following:

- Date and time of pack

- Permit or AK #

- Holding statement

- If the product is custom processed, a qualifying statement

Recall Plan

Attach a written recall plan that addresses steps i-v below and includes the position or person responsible for completing each step in the recall process (18 AAC 34.047).

Documentation of HACCP Training

Attach the certificate or written description of training for all individuals who are responsible for writing, reviewing, and revising HACCP plans and reviewing HACCP verification checks.

Following are some options for Seafood HACCP courses:

- Association of Food and Drug Officials Seafood HACCP Alliance

- Cornell University Seafood HACCP Course

- Alaska Sea Grant

Note: Other HACCP certifications or a written description of training from an individual that knows Seafood HACCP may be accepted, however, this knowledge must be reflected in the HACCP plan. If the HACCP plan does not show knowledge of Seafood HACCP, you will be required to take a Seafood HACCP course and obtain certification.

HACCP Plan

The HACCP plan must be specific to your operations and written according to the most current version of the FDA Fish and Fishery Products Hazards and Controls Guidance. The HACCP plan should also include all hazards identified during the hazard analysis.

Smoking Operations

If you are applying for Smoking-Hot, attach a heat distribution study for the smoker that shows the location of the coldest area in the smoker. The Seafood Technology Specialist at the Alaska Sea Grant can help you with the heat distribution study.

Cooking Operations: If you are applying for Cooking-Water, attach a cook study that evaluates the time it takes for the slowest heating portion of product to reach the required cook temperature. Also referred to as the minimum End Point Internal Product Temperature (EPIPT) or critical limit. An alternative would be to obtain a letter from a Process Authority.

The cook study and critical limit also needs to be referenced on the HACCP plan.

Ready-To-Eat Products

If you checked any of the ready-to-eat (RTE) processes listed in the application section, you must include product test results on the 12 random samples from the first lot produced that meet 18 AAC 34.125(d)(1) and (2), in order to be approved for any RTE processes.

- If you are producing a smoked RTE product that will be packed in Reduced Oxygen Packaging (ROP) and distributed refrigerated (not frozen), submit product test results showing the product contains at least 3.5% water phase salt or at least 3.0% water phase salt and not less than 100ppm nitrite.

Thermal Retort or Canning Operations

If you are applying for a PT-1 or PT2 permit, you must include the letter or cook schedule from a Process Authority for all retort or canning processes. In addition, you must register the cook schedule with the FDA and attach FDA forms 2541 and 2541d.

If you need a Process Authority, please contact the Alaska Sea Grant or Seafood Products Association.

Fees and Payment

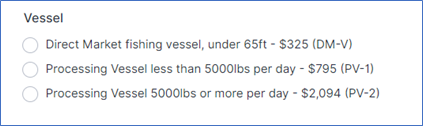

Permit Type

Select the permit type that best fits your operation and pounds of seafood products processed per day (averaged over a 7 day period).

- Direct Market (DM) permits are limited to the following activities: butchering, roe extraction, freezing, and packaging of the permit holders own catch.

- Definition of Butchering (18 AAC 34.990 (5)): to gut, gill, head, cut, fillet, or otherwise expose the flesh of a seafood product, including (A) exposing the scallop adductor muscle and (B) the recovery of roe when it will be processed or sold to be processed as a food product.

Note: Any activities not listed in this section, including buying fish to process, require a processor level permit (either a PL or PV).

- Thermal Processing (PT) permits are for canning and retort operations that produce a shelf stable product using a schedule approved by a Process Authority and filed with the FDA.

- IM-S Ice Manufacturer: this permit is for operations that only make and sell ice.

Note: Operations that process seafood in addition to making and selling ice, do not need to apply for an additional IM-S permit. These operations just need to include Ice Manufacturing when filling out the Processes section of the application.

If you are not sure of your permit type, contact us.

Payment

If you are paying by credit card, we will contact you within 5 business days for payment.

- Joy McLaurin

- Seafood Permitting Coordinator

- seafoodprocessing@alaska.gov

Indicates an external site.

Indicates an external site.